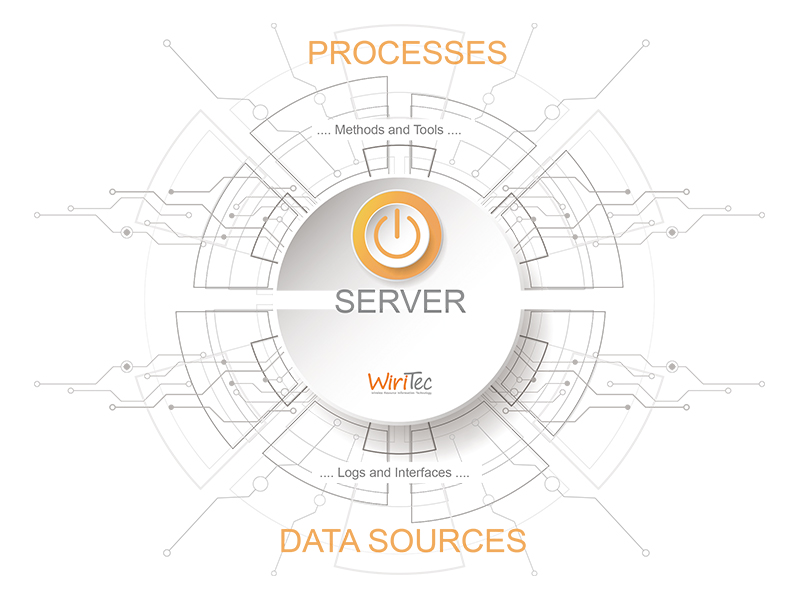

This is a specialized software process that accepts the values from the field or pre-systems, checks them for plausibility and stores original values as well as compressed or corrected values on the energy data server.

This simple and proven configuration can be easily adapted to security and performance requirements. It is very reliable and flexible. Installation and administration do not require any high demands. Within a very short time such a system can be set up on site and administrated and configured remotely.

Our approach for the entire field level is characterized by the fact that we are hardware-independent, highly flexible and manufacturer neutral. It is highly important for us not to change the collection infrastructure that we find. With the help of IT methods or field interfaces, we integrate existing control systems such as building automation, process control systems or other machine data collection into our system and import necessary data. Data loggers from third-party companies, existing collection systems or field devices with IT interfaces such as OPC UA or ModBus TCP are also connected via these paths. Meters, sensors or other devices that do not yet have an IT interface can be made intelligent with the WiriBox®. The WiriBox®, a Linux-based industrial PC, supports a variety of common field interfaces such as M-Bus, ModBus RTU and IEC 62056-21. In addition, sensors or other signal transmitters can also be connected directly to the WiriBox®.

The values collected with the help of the data connector from the field level and stored in the energy data server form the basis for all analyses and follow-up processes. The evaluation and further processing of data on the energy data server is made with the proven features of the C software platform. All analysis and evaluation processes as well as administrative features regarding the data server are implemented in the browser application. Therefore, no additional software has to be installed on the clients.

On the C platform the individual mapping of the customer processes with all workflows, evaluations or calculations is in the foreground. We use a modular set of flexible standard methods which has proven itself in hundreds of customer projects in order to realize individual customer processes.

These standard methods ensure that the system remains updateable in the future despite the high level of individualisation. These tools and methods include the powerful formula editor, the extensive chart engine but also descriptive attributes and elements as well as dashboards and reports for displaying performance indicators or states.

Typical customer processes which are implemented with these methods include accounting and cost allocations, forecasts, performance indicator calculations, measure management or maintenance processes.

The use of state-of-the-art IT technologies make it possible that processes or applications are not only limited to be used in an energy and resource management environment. We ensured that the methods we have implemented already represent processes from the world of digitisation and industry 4.0. The necessary collection and evaluation of high-frequency data from production installations via WiriBox® HF and InfluxDB, the analysis and simulation of installation states on the basis of consumption data, fault messages and maintenance information as well as the tracking of production batches with the help of digital twins: these and many others processes are possible with our methods.